Forging: our unique know-how

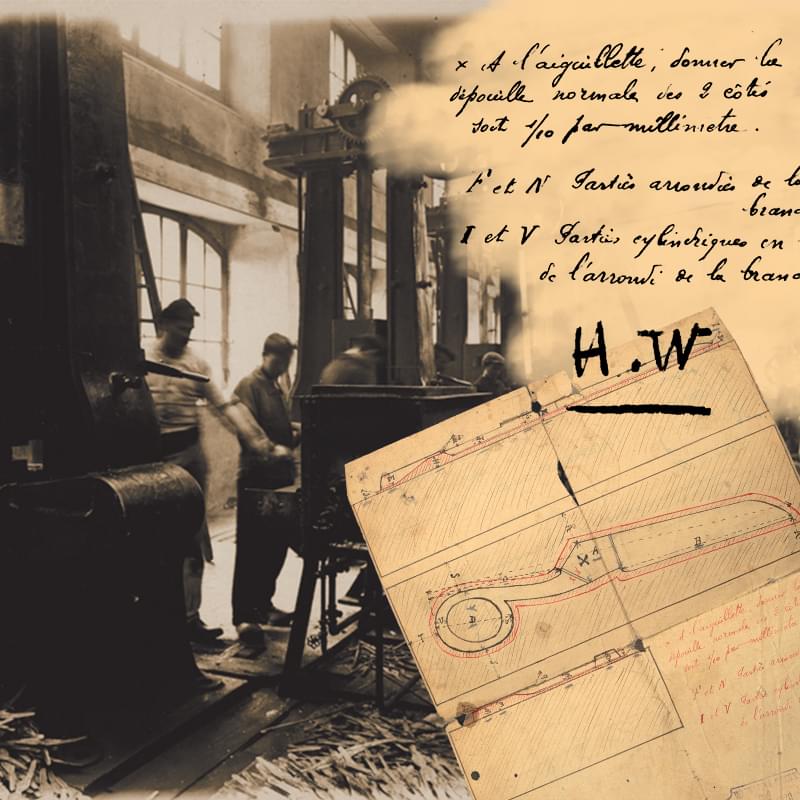

For more than 100 years our main mission has been to provide all our customers with quality products that ensure both safety and optimum performance for their sports and professional activities.

Wichard was founded in 1919 in Thiers by Henri Wichard. The company specialised initially in the manufacture of forged safety parts for industry.

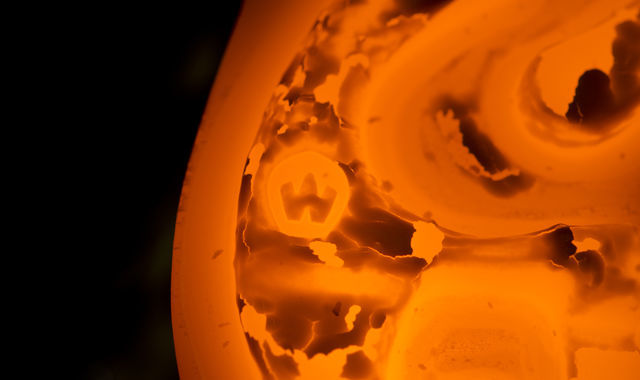

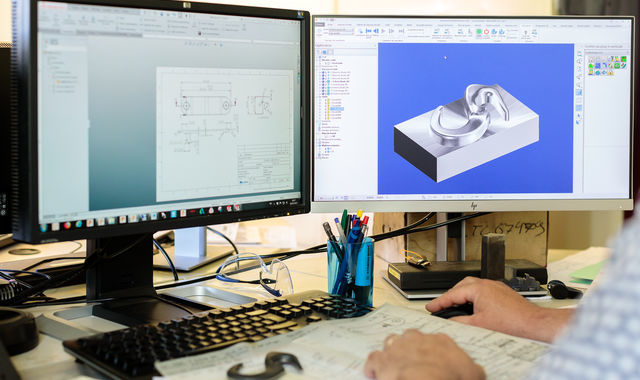

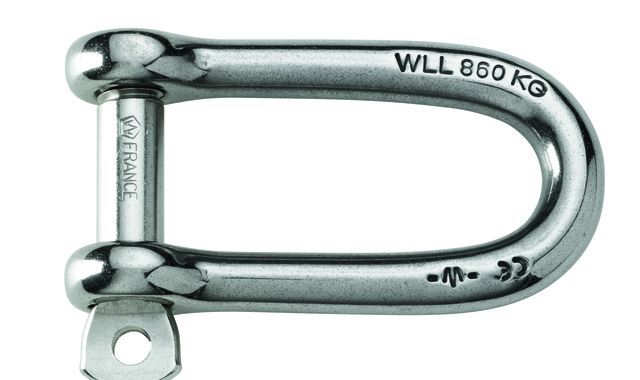

From the simple forged blank to the finished product, we provide global solutions adapted to your needs. By forging small parts from 1g to 1 kg, in medium or large series and using materials such as stainless steel or titanium. Our fields of application are varied: parachuting, aeronautics, medical, automotive, etc.

Choosing a Wichard product means above all choosing a quality product that will ensure safety and performance in all areas of application.

Why choose a Wichard forged product?

Guaranteed reliability

Made in france

Production and quality control

Proven corrosion resistance

Superior mechanical and fatigue strength

Eco friendly An eco-friendly company

Here at Wichard, we take our duty to protect the environment seriously. This dedication is reflected in our ISO 14001 certification, which we’ve had for many years. So what does this actually involve?

- Following all the applicable environmental laws, regulations and recommendations,

- Working constantly to reduce and eliminate pollution,

- Designing environmentally-friendly, recyclable products,

Reducing the environmental impact of our sites:

- By reducing our consumption of raw materials and energy,

- By using clean production processes,

- By avoiding any emissions into the environment which could pollute our air or waterways,

- By processing our waste efficiently.

- Working together with our partners and employees to keep on improving.