Inspection

A rigorous quality process

Wichard products are subject to extremely rigorous control procedures in order to guarantee their quality. To do this, we have the necessary means of control at our disposal:

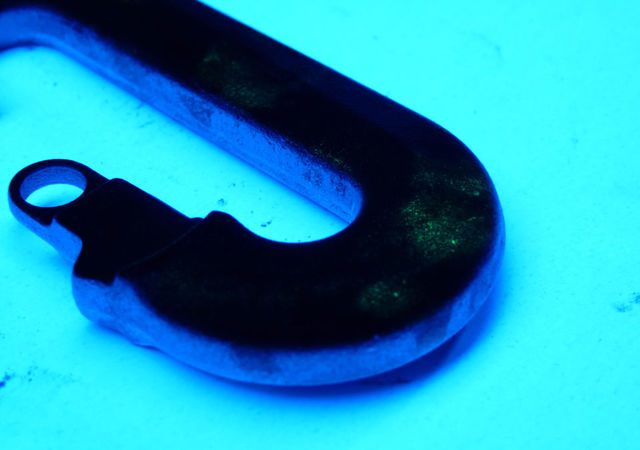

- Crack detection chain,

- Metallurgical analyses,

- Tensile tests (destructive testing on specimen/ destructive testing on final product)

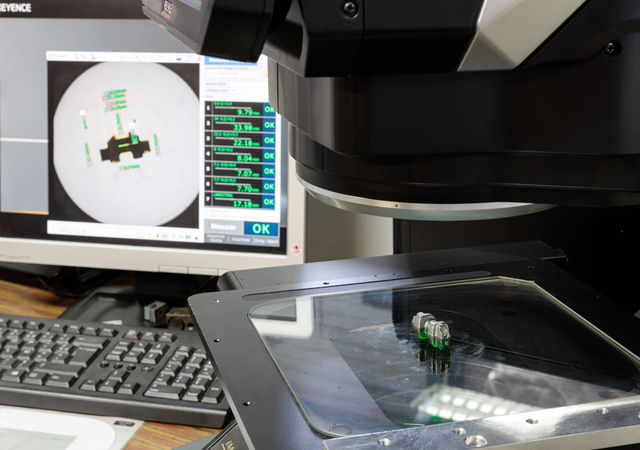

- Dimensional control

Certifications

Our commitment to quality, safety and respect for the environment is reflected in our numerous certifications.

Wichard is certified:

- ISO 9001 : 2015

- PPE category III

- ISO 14001 : 2015 for the environment

- ISO 13485 : 2016 for the medical sector

Material certificates

Material and conformity certificates according to EN 10204 are available on request by the customer at the time of ordering.

Certification 2.1: This indicates that the products are delivered in conformity with your order.

Certification 2.2: This indicates that the products delivered comply with your order and with the workload and breaking loads of the catalogue.

Certification 3.1: This indicates that the products delivered comply with your order and with the workload and breaking loads of the catalogue. It also includes the breaking loads measured on a specific manufacturing batch, as well as the batch number.

CE marking

As some of our products (shackles and carbine hooks) are considered to be lifting accessories, they are subject to CE marking by self-certification according to the Machinery Directive 2006/42.

Each marked product includes the following details

- Working Load Limit (WLL)

- CE marking, product origin, manufacturer's logo

- Carbine hooks have a serial number

Traceability

By marking its products with a W, Wichard guarantees their quality and origin. Our quality system ensures traceability throughout the manufacturing cycle: from the traceability of tools to the traceability of each batch at the various stages of manufacture. At the customer's request, additional traceability services can be set up.