Specialists in forged safety parts for industry

Guidance and support from design to delivery of finished products

Our business lines

Our business lines make it possible for us to provide global solutions adapted to the needs of our customers: from the simple forged blank to the finished product. Our Forging and Industry activity enables us to meet their expectations precisely by drawing up the specifications together.

Our high standards have enabled us to become a recognised player in fields where quality and safety are essential, such as aeronautics, the automotive industry and the medical sector.

Tooling

Forging

Treatments

Machining

Finishing

Assembly

Our services

Guaranteeing the success of your project is our main objective, which is why we offer you a range of services such as project management, drawing up specifications in joint consultation, forge simulation, industrialisation and traceability.

Project management

Project management

Project management allows us to dedicate a set of resources (studies, quality, production, quality control, etc.) to the different phases of the project in order to ensure tailor-made support.

On the basis of your specifications, each of our teams will provide its specific expertise: reengineering, design to cost, forging simulation, choice of materials, optimisation of manufacturing processes, etc.

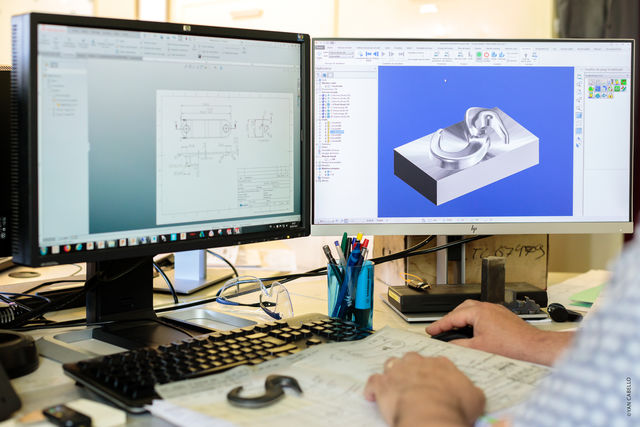

Study and simulation

Study and simulation

Our design office is in constant contact with your teams and designs the tools as well as providing its expertise in the choice of materials for a perfect adaptation to the environment and your use constraints.

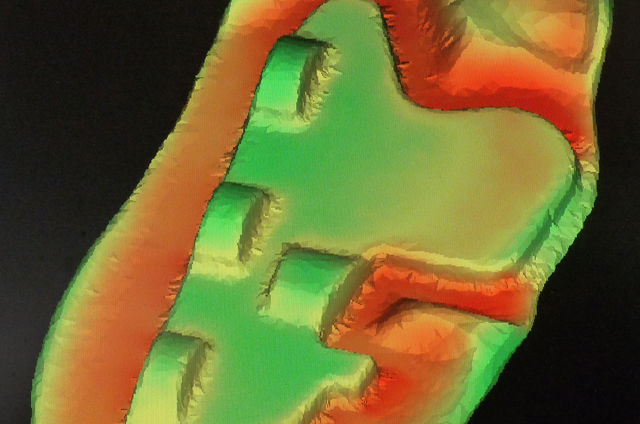

Forging simulations on specific software enable us to anticipate possible defects, limit product wear and tear and optimise material savings.

Industrialisation

Industrialisation

Industrialisation, as a key stage of the project, is ensured through complete control of the manufacturing chain: from the design and manufacture of the tools to production.

The development of manufacturing ranges allows the number of operations and production flows to be rationalised in order to generate cost optimisation.

Subcontracting operations carried out externally are made possible thanks to a large panel of local partners - partners with many years of experience and managed internally.

Production batches

Production batches

On customer request, Wichard can set up the traceability of a production batch from the supply of materials through the sub-contracting stages to the final stages of production. We can also set up a complete dossier including destructive and non-destructive testing and offer the possibility of marking each production batch.

Our strengths

A high-performance industrial park

- Two HSM (high-speed machining) centres for tool manufacturing

- One 3, 4 & 5 axis machining equipment

- Electroerosion machines

- Drop hammers with inertia (from 650 to 2,000 Kg/m) and hydraulic power for forging parts from 1 g to 1,000 g.

- Heat treatment furnaces

- Double-acting automatic forging line for large series - output: up to 2,200 parts/ hour

- Mechanical presses for workpiece trimming

- Finishing workshops for polishing and finishing parts

- Crack detection chain: non-destructive testing and quality control

- Salt spray chamber: checking the parts for corrosion resistance

- Machining and assembly workshops for standard parts

- Special machines dedicated to special manufacturing jobs

Women, men and 100 years of know-how

Our teams are committed to customer satisfaction. Our shared values are a passion for forging, pride in our work, professional development, and craftsmanship.

- 60% of our employees are between 40 and 55 years old

- Training time for a forging press worker: 3 and 5 years

- Forging press team :

- Continuous training through mentorship and tutoring

- Youngest forging press worker: 36 years old - average age 44 years old among the forging press workers

- Design office team :

- Personnel specialised and trained in the thermal transformation business

- CAD and CADD software - Creo and Solidworks, CAM software, forging simulation software

- Quality control team :

- Present at all stages of production from the supply of the material to dispatch

- Young team: average age 35 years old

- Composed of 1 quality control manager and inspectors, 1 HSE manager

- COFREND certification: certification of personnel for non-destructive testing

Contact us

Wichard

1 ZI de Felet, CS 50085

63307 Thiers, France

Tél : +33 (0)4 73 51 65 00